切换至摄影模板

博文

ISUZU 6WF1-TC Engine installation Instructions

|

ISUZU G-IDSS Diagnostic Service System 10.2023 Download and Installation Service

Lock the wheels.

·Attach wires securely to the engine,and hoist it.

·Do not position yourself underneath the engine while it is being hoisted.

·Never put your hands where they may be pinched or sandwiched.

·The engine is heavy so proceed with the work with all due care.

1.Engine assembly

Hoist the engine slowly,and install it in place.Do this work while taking care to avoid interference with other parts.

·CAUTION:

Never position yourself underneath the engine when it

HCW31BSH055401

Legend

1.Engine foot

is being hoisted

2.Engine mounting

Install the engine mounting,and tighten it to the specified torque.

Front tightening torque:N.m (kgf·m/lb.ft)

Rubber nut Engine side (6) 228 (23.2/168)

Chassis side 113(11.5/83)

(2)

Bracket Frame side (5) 157(16.0/116)

HCW31BSH055401

Legend

1. Engine foot

2. Nut (chassis side)

3. Bracket

4. Frame

5. Bolt (frame side)6. Nut (engine side)

Chassis side 113(11.5/83)

Rear tightening torque:N.m(kgf.m/lb.ft)

Rubber bolt

Engine side(1) 490(50.0/362)

Chassis side (2 157(16.0/ 116)

3.Fuel hose

Install the IN and OUT of the fuel hose.

4.Ground wire

Connect the starter ground wire (1)to the frame.

5.Shift selector rod

6.Engine speed sensor connector

7.Power steering pump

Install the power steering pump,and tighten it to the specified torque.

Tightening torque: 39N·m(4.0kgf·m/29lb·ft)

Install the suction pipe and governor pipe of the air

compressor.

8.EGR valve air hose

9.Air compressor hose

10.Air cylinder hose

11.Sub tank hose

12.Engine harness connector

Connect the connectors securely.

13.Oil pressure switch

14.Dual thermo sensor connector

15.Starter wires

16.Generator connector

17.A/C compressor

Install the A/C compressor,and tighten it to the specified torque

04.2023 ISUZU E-IDSS Diagnostic Software Download and Installation Service

Tightening torque 20N·m(2.0kgf·m/14|b·ft))

Install the A/C compressor belt, harness

connectors and gas pipe clips.

Adjust the belt tension.(For details on adjusting

the belt tension,refer to the section on inspections and maintenance.)

18.Cab back member

Install the cab back member,and tighten it to the specified torque

Tightening torque: 155N·m(15.8kgf·m/114lb·ft))

Install the oil pipe (2)for tilting the cab.

Connect the air hose and its connectors to the cab back member.

Install the oil tank (1)of the power steering pump. Install the cab back member noise cover (2).

Purge the air in the cab tilt pump.

ISUZU IDSS MX2-T Diagnostic Adapter System Support G-IDSS/US-IDSS/E-IDSS(Included DHL Shipping

19.Exhaust pipe front and exhaust brake

Install the exhaust pipe front (1)and exhaust brake (3),and tighten it to the specified torque.

Install the heat protector (2).

HCW31BSH054101

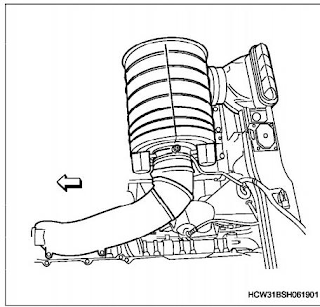

20.Air cleaner assembly

Install the air cleaner assembly,and connect the air duct and its connectors.

21.Mud guard

22.Side noise cover

23.Oil filler pipe

Tightening torque: 59N·m(6.0kgfm/43lb·ft))

24.Oil level gauge

25.Radiator hose

After installing the air purging hose,upper hose and lower hose,connect the harness.

HCW31BSH053601

26.Inter-cooler hose

27.Pour in the cooling water.

28.Transmission assembly

For details on installing the transmission assembly, refer to the chapter on removing and installing the transmission.

HCW31BSH055B0

11.2023 ISUZU US-IDSS Diagnostic Service II Truck Diagnostic System Download and Installation

29.Exhaust pipe

30.Battery cable

Connect the battery cable (1).

Inspections and adjustments after installation

·Supply and check the engine oil and cooling water.

·Inspect and check the idling speed.

·Inspect and check the clutch pedal play.

·Adjust the pulling reserve of the parking brake

lever.

·Clear away the rags from around the engine and

any other items that may be snagged by the

engine parts,and wipe off any engine oil and other

substances on the engine.

·Check that the shift lever is at the neutral position,

call out to warn any persons in the vicinity,start up

the engine using the starter switch of the driver's

seat,and check that the engine starts up and stops

properly.

·Check for leaking oil or water from the engine

parts.

·Check for leaking fuel,oil and air from the pipe

connections.

·Check that no unusual sounds are heard from any

of the parts

·Check that no exhaust gas is leaking and that the

exhaust gas is colorless.

·After stopping the engine,inspect whether the oil

and cooling water are within the prescribed levels.

·Go for a test drive,and check that there are no

problems.

免责声明:本文中使用的图片均由博主自行发布,与本网无关,如有侵权,请联系博主进行删除。

上一篇:

How to Remove/ Replace DOOSAN 440 Plus,460 Series,470 Plus SKID STEER LOADER .

下一篇: ISUZU 6WF1-TC Engine Disassembly Instructions

下一篇: ISUZU 6WF1-TC Engine Disassembly Instructions

全部作者的其他最新博文

- • the hydraulic release of the single hydraulic circuit of the caterpillar311D LRR

- • JCB Backhoe Loader Power Shift - Chain Adjustment

- • Perkins 2806F Engine Inlet and Exhaust Valve Springs - Remove and Install

- • Caterpillar 312D2 and 313D2 Excavator 3054C Engine System Pressure- -Release

- • Parking Brake Lining Clearance and Lever Travel Adjustment on Isuzu Vehicles

- • Doosan DA30 Dump Truck the ECU Wiring Tier2 -Removal