博文

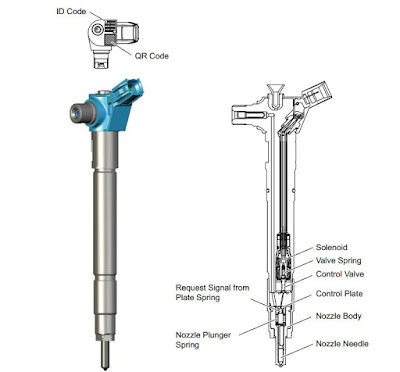

Toyota 1GD/2GD Engine Common Rail System Injection How to Work

||

Possesses the capability to withstand extra-high voltage of 220 MPa.

Specifications

that prevent static leaks * have been realized through the use of a

construction that eliminates high pressure sliding surfaces. These

static leakless characteristics improve fuel efficiency by upgrading

power performance and suppressing rises in fuel temperature.

Before Injection

When the solenoid is not energized, the control valve is closed to shut off the sub "out" orifice by the force of the valve spring. As a result, injection cannot take place with the nozzle needle closed due to the difference in surface area exposed to pressure between the control chamber side of the nozzle needle and the nozzle seat side (control chamber side > nozzle seat side).

During Injection

When the solenoid is energized, it pulls the control valve upward, and fuel inside the control chamber flows out from the sub "out" orifice and the control plate "out" orifice. The pressure becomes greater on the nozzle needle side than the control chamber side due to the drop in pressure within the control chamber. As a result, the force applied to the nozzle seat overcomes the force pressing down, the nozzle needle is pushed up, and injection begins. Additionally, the control plate is pushed up due to both a pressure difference (control chamber side > middle chamber side) and the force of the control plate spring, which closes the "in" orifice. For this reason, dynamic leaks during injection* are minimized by only holding the remaining fuel in the control chamber.

Denso ETSI Fuel Injection Pumps 2017 2015 2012 Free Download

Injection Complete

When

the solenoid power supply is stopped, the control valve closes the sub

"out" orifice, fuel inside the control chamber flows into the

intermediate pressure chamber and increases the pressure of the

intermediate pressure chamber. Afterwards, the combined pressure of the

control chamber side and control plate spring becomes less than the

combined pressure of the intermediate pressure chamber side and the high

pressure

annular groove. As a result, the control plate lowers, and fuel flows

into the control chamber from the "in" orifice. The force pressing down

on the nozzle needle is increased due to an increase in pressure inside

the control chamber, the nozzle needle lowers, and injection ends.

Afterwards, the pressure in the control chamber, intermediate pressure

chamber, and high pressure annular groove become equal, and the control

plate is pushed up by the control plate spring.

www.car-auto-repair.com

免责声明:本文中使用的图片均由博主自行发布,与本网无关,如有侵权,请联系博主进行删除。